Heat Treatment Rectifier for Galvanizing

AC current heating is used for heating thin-section parts and induction technique. AC current effect the outer surface of the component that it passes through and on big components there may be a heat difference between the center and the outer surface. But DC current uses all cross-section of the material that it passes through and the heat distribution would be the same all around the component.

Heat Treatment Rectifier Technical Specs

Usage Areas Sintering Applications

Hot Pressing

Aluminum Billet Heating

Annealing Furnaces

Cooking Drying Ovens

Ceramics / Glass Furnaces

Vacuum Heating Applications

Thyristor Controlled Furnace Heating Control

In traditional contactor systems furnace resistors were damaged because of problems such as sudden increase/decrease on the network. In thyristor controlled systems, the current applied to system inceases slowly rises and the working heat is obtained without harming the resistors. Then,according to the mode of operation, current-limited or power-limiting as the temperature control is applied.

The system has over current, missing phase properties which ensures solving problems without damaging resistors. In low powered ones air cooling is used but in high power ones water cooling can be used. There phases can be used at the same time as well as each phase can be controlled separately.

DC Heating System

In DC heating system the component which would be heated is passes through direct current and heated acording to current severity. DC current uses all cross-section of the component and yet the higher performance is obtained within lower period of time. Rational or on/off control applications may be used at the same time.The system can be produced air cooled or water cooled depending on the power. The system has over current, missing phase properties which ensures full protection.In DC heating the consumption of energy is distributed to three phases equally , thinner cables are used so the compensation is less needed Also power factor is increased so the total sum of the bill for reactive consumption is less. In DC heating systems special semi-conductors are used to increase the efficiency.

Control: Mak Plus Power Systems Microprocessor Control System

Input Voltage: 220 VAC, 50 Hz, single phase / three-phase 3x380 VAC, 50 Hz.

Output Voltage: AC Control 0-380 V / 0 ... 220 V

DC Control: 0 ... 25 V

Output Power: 1 ... 2000 kVA

Measurement: True RMS Current - Voltage measurement - Temperature measurement

Yield: % 60 to 92

Output Control: 0 - 100% between the current - voltage power regulation

Cooling: Air, Water, Oil, Mixed

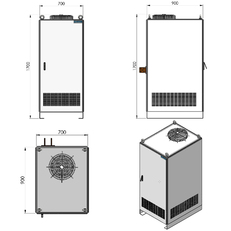

Cabins: modular assembly, painted, standing or wheeled steel chassis

Transformer: High-efficiency, transformer Mak plus rectifier TSE

Color: RAL 7032

Study: Temperature control using PID, on / off

Interface: Digital inputs with the on / off to increase, decrease

Analog Reference: On / Off 0-10 V with reference to current, voltage, power or temperature control to select

Temperature Measurement: 2-channel temperature input / PT100-000-600 C / Thermocouple -200 to - 1600 C / JKNEL type thermocouple / 4-20 mA with analog reference / 200-3000 C

Warning: Failure and status information relays

Protection Features: Phase missing / over current / over temperature / short circuit / thyristor failure / diode failure

Input Voltage: 220 VAC, 50 Hz, single phase / three-phase 3x380 VAC, 50 Hz.

Output Voltage: AC Control 0-380 V / 0 ... 220 V

DC Control: 0 ... 25 V

Output Power: 1 ... 2000 kVA

Measurement: True RMS Current - Voltage measurement - Temperature measurement

Yield: % 60 to 92

Output Control: 0 - 100% between the current - voltage power regulation

Cooling: Air, Water, Oil, Mixed

Cabins: modular assembly, painted, standing or wheeled steel chassis

Transformer: High-efficiency, transformer Mak plus rectifier TSE

Color: RAL 7032

Study: Temperature control using PID, on / off

Interface: Digital inputs with the on / off to increase, decrease

Analog Reference: On / Off 0-10 V with reference to current, voltage, power or temperature control to select

Temperature Measurement: 2-channel temperature input / PT100-000-600 C / Thermocouple -200 to - 1600 C / JKNEL type thermocouple / 4-20 mA with analog reference / 200-3000 C

Warning: Failure and status information relays

Protection Features: Phase missing / over current / over temperature / short circuit / thyristor failure / diode failure