Usage Areas

|

Electro Plating

Catastrophes Paint Anodizing Plating Aluminium Surface Treatments Varnishing Corrosion Prevention |

Refining Operations

Chlorine Electrolysis Electric Oil Import Erosion Metal Plating on Plastics edit. |

New AC Drive Unit

Mak Plus Power Systems electro plating rectifier is equipped with the new AC power control unit. With this unit rectifier faults comes down to minimum as well as increases working yield and rectifier functions. With this new AC drive unit errors are prevented before they occur.Through this it can be used in even the most difficult circumstances safely. The new drive system has ability to work with remote control and automation system at the same time.In addition to a large number of features, as well as additional features are also available to be made over time.

Timer

With the timer on the program is is possible to set working for a limited time or continuously.On limited time rectifier works until till reaches to the desired value and stops automatically.At the end of process a warning warns the operator.On continuous working it goes on working until the operator ends the process.

Ampere / hour and Auto Dosing

Mak Plating rectifiers have ampere/Hour calculation feature. In this way the most reliable data were obtained about the process of working in the bathroom. Plating process can be adjusted with ampere/hour instead of time. Operator panel for both the coating process is ongoing as well as for the sum of all transactions are different counters. This counters can also be used to add chemicals to the pool automatically. Especially in critical baths the chemical concentration is very important. Mak plus power systems rectifiers helps you for chemical control as well as giving information for working and yield of the system.

Selective working program

In most of the plating pools selective working program is used to remove undesired metals from the pool. But this process is made manually or by an external device.In Mak plating rectifiers this is done automatically with this selective working program.After the process starts, the output voltage is increased from zero and turns to zero again periodically.This process is repeated by definitely or indefinitely.In such way the selective working is done easily which is a very hard maintenance process.

Easy to use

Mak Standard Plating rectifiers have a very simple running program. With the remote control unit the operator can run the device without going near to it. The system is fully compatible with all automation systems which also can work either manually or with automation system together.

Mak Plus Power Systems electro plating rectifier is equipped with the new AC power control unit. With this unit rectifier faults comes down to minimum as well as increases working yield and rectifier functions. With this new AC drive unit errors are prevented before they occur.Through this it can be used in even the most difficult circumstances safely. The new drive system has ability to work with remote control and automation system at the same time.In addition to a large number of features, as well as additional features are also available to be made over time.

Timer

With the timer on the program is is possible to set working for a limited time or continuously.On limited time rectifier works until till reaches to the desired value and stops automatically.At the end of process a warning warns the operator.On continuous working it goes on working until the operator ends the process.

Ampere / hour and Auto Dosing

Mak Plating rectifiers have ampere/Hour calculation feature. In this way the most reliable data were obtained about the process of working in the bathroom. Plating process can be adjusted with ampere/hour instead of time. Operator panel for both the coating process is ongoing as well as for the sum of all transactions are different counters. This counters can also be used to add chemicals to the pool automatically. Especially in critical baths the chemical concentration is very important. Mak plus power systems rectifiers helps you for chemical control as well as giving information for working and yield of the system.

Selective working program

In most of the plating pools selective working program is used to remove undesired metals from the pool. But this process is made manually or by an external device.In Mak plating rectifiers this is done automatically with this selective working program.After the process starts, the output voltage is increased from zero and turns to zero again periodically.This process is repeated by definitely or indefinitely.In such way the selective working is done easily which is a very hard maintenance process.

Easy to use

Mak Standard Plating rectifiers have a very simple running program. With the remote control unit the operator can run the device without going near to it. The system is fully compatible with all automation systems which also can work either manually or with automation system together.

Optional Properties

Profibus DP

- 12mbit Profibus DP concordance,opportunuty to connect single or in groups ProfiNet- 100 Mbit

ProfiNet

Concordance,opportunuty to connect single or in groups

Modbus-

Modbus communications over Ethernet or RS485

Ethernet Serial Communication

-Communication over RS 232 or RS485 on Mak Plus or a different protocol 100Mbit wired, 54 Mbit wireless

Analog Reference

- 0-10 V or 4-20 mA DC signal and the Current - Voltage control

PC Control

-Serial and Wireless Communication over RS 232/485 on MRS control software

PLC Control-

Ability to control motor system with two relay contact

- 12mbit Profibus DP concordance,opportunuty to connect single or in groups ProfiNet- 100 Mbit

ProfiNet

Concordance,opportunuty to connect single or in groups

Modbus-

Modbus communications over Ethernet or RS485

Ethernet Serial Communication

-Communication over RS 232 or RS485 on Mak Plus or a different protocol 100Mbit wired, 54 Mbit wireless

Analog Reference

- 0-10 V or 4-20 mA DC signal and the Current - Voltage control

PC Control

-Serial and Wireless Communication over RS 232/485 on MRS control software

PLC Control-

Ability to control motor system with two relay contact

Technical Specification

Operation: Manual operator panel / automation system

Control: Mak Microprocessor Control System

Input Voltage: 3x380 VAC, 50 Hz three-phase.

Output Voltage: Standard: 0 .. 25 VDC / Special design for over 25V

Output Current: 100 A - 50 kA

Ripple Factor: % 5 to 7

Measurement: True RMS Current - Voltage Measurements

Yield: % 80 to 95

Indicators: LCD Display, current, voltage, time, message ampere hour imaging, German / English language selection

Output Control: 0 - 100% between the current - voltage regulation

Pulse - Base Control: Optional

Cooling: Air, Water, Oil, Mixed

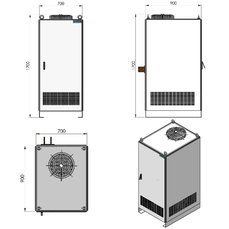

Cabins: modular assembly, painted, standing or wheeled steel chassis

Win: Wave-walled, sanded, phosphates, interior and exterior painted, wheeled steel boiler

Transformer: High-efficiency, transformer MAK PLUS Rectifier

Color: RAL 7032 / Green

Programmed Operation: 10 Step - 10 Program / Option: 100 Program

Timer: Default

Ampere hour Counter: Process and total ampere hour counter, the set value, dosing information, programs to choose from within the ampere minute or ampere second

Remote Control: External operator panel, with communication cable RS485, 1 km from a distance of portable, wireless 100 mt. up to a distance, with all functions

Warning: Failure and status information relays

Protection Features: Phase missing / over current / over temperature / short circuit / thyristor failure / diode failure

Control: Mak Microprocessor Control System

Input Voltage: 3x380 VAC, 50 Hz three-phase.

Output Voltage: Standard: 0 .. 25 VDC / Special design for over 25V

Output Current: 100 A - 50 kA

Ripple Factor: % 5 to 7

Measurement: True RMS Current - Voltage Measurements

Yield: % 80 to 95

Indicators: LCD Display, current, voltage, time, message ampere hour imaging, German / English language selection

Output Control: 0 - 100% between the current - voltage regulation

Pulse - Base Control: Optional

Cooling: Air, Water, Oil, Mixed

Cabins: modular assembly, painted, standing or wheeled steel chassis

Win: Wave-walled, sanded, phosphates, interior and exterior painted, wheeled steel boiler

Transformer: High-efficiency, transformer MAK PLUS Rectifier

Color: RAL 7032 / Green

Programmed Operation: 10 Step - 10 Program / Option: 100 Program

Timer: Default

Ampere hour Counter: Process and total ampere hour counter, the set value, dosing information, programs to choose from within the ampere minute or ampere second

Remote Control: External operator panel, with communication cable RS485, 1 km from a distance of portable, wireless 100 mt. up to a distance, with all functions

Warning: Failure and status information relays

Protection Features: Phase missing / over current / over temperature / short circuit / thyristor failure / diode failure