Usage Areas of Rectifier

|

Agricultural Equipment

Hand Tools Cars Automotive Parts Shipping Supplies Transformers Metal Office Furniture |

Garden Equipment & Furniture Fasteners Cutting Tools White Goods Radiators Industrial Machine Parts |

Catapharosis Rectifier Technical Details

Mak Plus Power Systems Cataphoresis rectifiers are equipped with the features needed for this process. Rectifier can be made by using ramp, current voltage control etc. properties on the work program so that the paint thickness would be obtained standard. Many steps can be defined by the program and different running time and voltages can be defined for each step.The device can be connected to any automation system as well as it can work manually. Automation system can be controlled by serial communication by an analog reference or by on/off control. It also applies waiting current on failure situations to prevent components from damage by non-current situation. Cataphoresis rectifiers which are manufactured thyristor controlled , can be manufactured 6 pulse or 12 pulse. It presents an extremely sensitive voltage control. Although ten sion control is used in cataphoresis processes current control can also be used.

|

Easy Installation Ease of Maintenance Operator Panel, PC or PLC control ProfibusDP Comprehensive Error Diagnostics User-Friendly Design Wide Program Options Functional Control Panel Options Smart Bug Tracking System Superior Protection Against User Errors Easy to suplly spare parts Environmental design Energy-saving system Different line voltage selector |

PC Control

-Serial and Wireless Communication over RS 232/485 on Mak Plus Rectifier control software PLC Control- Ability to control motor system with two relay contact External Start / Stop- 0-1 with a key or a NO relay contactExternal Program Selection- 4-bit digital input with selection of 16 program Profibus DP - 12mbit Profibus DP concordance,opportunuty to connect single or in groupsProfiNet- 100 Mbit ProfiNet concordance,opportunuty to connect single or in groups Modbus- Modbus communications over Ethernet or RS485 Ethernet Serial Communication -Communication over RS 232 or RS485 on Mak Plus Rectifier Controller or a different protocol 100Mbit wired, 54 Mbit wireless Analog Reference- 0-10 V or 4-20 mA DC signal and the Current - Voltage control Internet Access- Dial up or ADSL line connection on the remote devices being able to establish control of all kinds to make the program update |

Optional Properties

Technical Properties

Operation: Manual Operator Panel / Automation

Control: PLC control system Siemsns / Mak Plus Rectifier microprocessor control system

Input Voltage: 3x380 VAC, 50 Hz, Three Phase

Output Voltage: 50-600 VDC Standard

Output Current: 1-50 kA

Power Control: 300 Hz Pulse 6 / 600 Hz 12 Pulse Thyristor Module

Yield:% 85 to 92

Indicators: Touch color LCD screen, current, voltage, time, amperehour, message display, Turkish-English language selection

Measurement: The current-voltage measurement TrueRMS Output Control: 0-100% between the current-voltage control

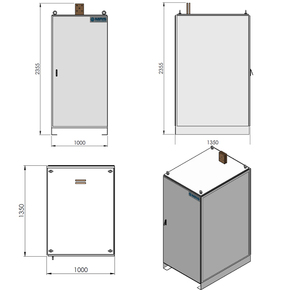

Cooling: Air, Oil, Water, Mixed Cabin (Air - Water Cooled): Modular mounted, painted, standing or wheeled steel chassis

Boiler (oil cooling): Wave-walled, sanded, phosphated, interior and exterior painted, wheeled 3-mm steel boiler Installation: standardized, modular system Transformer: High-efficiency, transformer MRS TSE / High-efficient, column-type

MRS Variac Color: Standard: Cream, Green / Option: RAL colors Catalogue

Programmed Operation: Automatic coating thickness control, Micron calculation system, 10 different programs

Timer: Default Amperehour Counter: Process and total amperehour counter, the set value, dosing information, programs to choose from within the ampereminute or ampere second.

Ramp Function: The user-defined, unlimited

Pool Temperature Control: the specified limits, to control the cooling system

Remote Control: External operator panel, with communication cable RS485, 1 km. from a distance of portable, wireless 100 mt. up to a distance, has all the functions

Warning - Warning: Rectifier fault and status relay information

Protection Features Phase missing, excessive current, excessive heat, Short-circuit

Control: PLC control system Siemsns / Mak Plus Rectifier microprocessor control system

Input Voltage: 3x380 VAC, 50 Hz, Three Phase

Output Voltage: 50-600 VDC Standard

Output Current: 1-50 kA

Power Control: 300 Hz Pulse 6 / 600 Hz 12 Pulse Thyristor Module

Yield:% 85 to 92

Indicators: Touch color LCD screen, current, voltage, time, amperehour, message display, Turkish-English language selection

Measurement: The current-voltage measurement TrueRMS Output Control: 0-100% between the current-voltage control

Cooling: Air, Oil, Water, Mixed Cabin (Air - Water Cooled): Modular mounted, painted, standing or wheeled steel chassis

Boiler (oil cooling): Wave-walled, sanded, phosphated, interior and exterior painted, wheeled 3-mm steel boiler Installation: standardized, modular system Transformer: High-efficiency, transformer MRS TSE / High-efficient, column-type

MRS Variac Color: Standard: Cream, Green / Option: RAL colors Catalogue

Programmed Operation: Automatic coating thickness control, Micron calculation system, 10 different programs

Timer: Default Amperehour Counter: Process and total amperehour counter, the set value, dosing information, programs to choose from within the ampereminute or ampere second.

Ramp Function: The user-defined, unlimited

Pool Temperature Control: the specified limits, to control the cooling system

Remote Control: External operator panel, with communication cable RS485, 1 km. from a distance of portable, wireless 100 mt. up to a distance, has all the functions

Warning - Warning: Rectifier fault and status relay information

Protection Features Phase missing, excessive current, excessive heat, Short-circuit