Anodising Rectifiers

Basically the system running in the special program of study with voltage-controlled output voltage ramp to the desired period of time given as a constant voltage control is provided.

With the automatic micron calculation system apart from the component number desired micron thickness is plated automatically by the system. At the same time the bath temperature is controlled to ensure ideal anodizing process.

USAGE AREAS

|

USAGE AREAS

|

General Technical Specifications

Plating Thickness Control Mak Plus Rectifier control system perceives the surface of the component automatically and calculates the necessary operation time for the desired thickness . The operator just enters the value of desired thickness and pushes the start button. All the other processes are made by the rectifier automatically.

Measuring Temperature Anodizing bath should be between 18 - 22 C.Pool temperature is measured by the rectifier and shown on the panel so there won’t be an external measurement needed which allows easier operation.

Pool Temperature Control The minimum and maximum pool temperature values are entered in anodizing programs. The rectifier measures the pool temperature and checks the conformity to the given values and runs the cooling system if needed and stops when it is reached to the desired temperature so there is no need for complex temperature control mechanisms.

Recipe SystemThe running program is kept in record of the system for aluminum components with different characteristics. The recipe on the system record is loaded for the different component and process can be started faster which also ensures standard production as well as keeping out from conflict of which recipe should be applied.

Functional Operator PanelThe operator panel designed for anodizing rectifiers has touchscreen ,colored and wide screen. All functions of the device can be defined on this screen including calibration process, preparing recopies for components. The operator panel has IP65 protection class which is not effected by the moisture,acid etc.. at the environment and can be used for years safely.

PLC Control System Mak Plus Power Systems Anodizing Rectifier have PLC control system which are durable for years and high reliability since they are made by industrial components. It’s open to innovations with flexible programming features.If the device is required to work with an outer system it can be adopted to any automation system easily.

Measuring Temperature Anodizing bath should be between 18 - 22 C.Pool temperature is measured by the rectifier and shown on the panel so there won’t be an external measurement needed which allows easier operation.

Pool Temperature Control The minimum and maximum pool temperature values are entered in anodizing programs. The rectifier measures the pool temperature and checks the conformity to the given values and runs the cooling system if needed and stops when it is reached to the desired temperature so there is no need for complex temperature control mechanisms.

Recipe SystemThe running program is kept in record of the system for aluminum components with different characteristics. The recipe on the system record is loaded for the different component and process can be started faster which also ensures standard production as well as keeping out from conflict of which recipe should be applied.

Functional Operator PanelThe operator panel designed for anodizing rectifiers has touchscreen ,colored and wide screen. All functions of the device can be defined on this screen including calibration process, preparing recopies for components. The operator panel has IP65 protection class which is not effected by the moisture,acid etc.. at the environment and can be used for years safely.

PLC Control System Mak Plus Power Systems Anodizing Rectifier have PLC control system which are durable for years and high reliability since they are made by industrial components. It’s open to innovations with flexible programming features.If the device is required to work with an outer system it can be adopted to any automation system easily.

Optional Properties

PC Control -Serial and Wireless Communication over RS 232/485 on Mak Plus rectifier control software

PLC Control- Ability to control motor system with two relay contact

External Start / Stop- 0-1 with a key or a NO relay contact

External Program Selection- 4-bit digital input with selection of 16 program

Profibus DP- 12mbit Profibus DP concordance,opportunuty to connect single or in groupsProfiNet- 100 Mbit

ProfiNet concordance,opportunuty to connect single or in groups

Modbus- Modbus communications over Ethernet or RS485

Ethernet Serial Communication-Communication over RS 232 or RS485 on Mak Plus Rectifier or a different protocol 100Mbit wired, 54 Mbit wireless

Analog Reference- 0-10 V or 4-20 mA DC signal and the Current - Voltage control

Internet Access- Dial up or ADSL line connection on the remote devices being able to establish control of all kinds to make the program update

PLC Control- Ability to control motor system with two relay contact

External Start / Stop- 0-1 with a key or a NO relay contact

External Program Selection- 4-bit digital input with selection of 16 program

Profibus DP- 12mbit Profibus DP concordance,opportunuty to connect single or in groupsProfiNet- 100 Mbit

ProfiNet concordance,opportunuty to connect single or in groups

Modbus- Modbus communications over Ethernet or RS485

Ethernet Serial Communication-Communication over RS 232 or RS485 on Mak Plus Rectifier or a different protocol 100Mbit wired, 54 Mbit wireless

Analog Reference- 0-10 V or 4-20 mA DC signal and the Current - Voltage control

Internet Access- Dial up or ADSL line connection on the remote devices being able to establish control of all kinds to make the program update

Technical Specification

Operation: Manual Operator Panel / Automation

Control: PLC control system Siemsns / Mak Plus Rectifier microprocessor control system

Input Voltage: 380V, 400V, 415V, 220V Three Phase AC, 50 Hz-60Hz, Three Phase

Output Voltage: Standard 15-25 V / Hard Anodized: 40-70 VDC

Output Current: 1-50 kA

Power Control: 300 Hz to 6 Pulse / 12 Pulse of 600 Hz (Thyristor Module)

Ripple Factor: 300 Hz to 6 Pulse: 5-7% / 600 Hz 12 Pulse: 1-3%

Yield / Efficiency: % 85 to 95

Indicators: Touch color LCD screen, current, voltage, time, amper hour, message display, English language selection

Measurement: True RMS The current-voltage measurement, temperature measurement of the pool

Output Control: 0-100% between the current - voltage control Pulse-Base Control: Optional

Cooling: Air, Oil, Water, Mixed

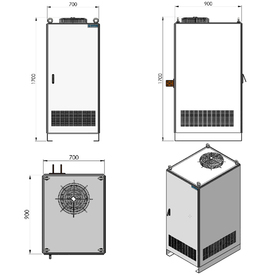

Cabin (Air - Water Cooled): Modular mounted, painted, standing or wheeled steel chassis

Boiler (oil cooling): Wave-walled, sanded, phosphated, interior and exterior painted, wheeled steel boiler

Installation: standardized, modular system

Transformer: High-efficiency, transformer Mak Plus Rectifier TSE

Color: Standard: Cream and Green / Option: RAL colors Catalogue

Programmed Operation: Automatic coating thickness control, Micron calculation system, 10 different programs

Timer: Default

Amperehour Counter: Process and total amperehour counter, the set value, dosing information, programs to choose from within the ampereminute or amperesecond

Ramp Function: The user-defined, unlimited

Pool Temperature Control: the specified limits, to control the cooling system

Remote Control: External operator panel, with communication cable RS485, 1 km. from a distance of portable, wireless 100 mt. up to a distance, has all the functions

Warning: Rectifier fault and status relay information

Protection Features: Phase missing, over current, overheat, short circuit

Control: PLC control system Siemsns / Mak Plus Rectifier microprocessor control system

Input Voltage: 380V, 400V, 415V, 220V Three Phase AC, 50 Hz-60Hz, Three Phase

Output Voltage: Standard 15-25 V / Hard Anodized: 40-70 VDC

Output Current: 1-50 kA

Power Control: 300 Hz to 6 Pulse / 12 Pulse of 600 Hz (Thyristor Module)

Ripple Factor: 300 Hz to 6 Pulse: 5-7% / 600 Hz 12 Pulse: 1-3%

Yield / Efficiency: % 85 to 95

Indicators: Touch color LCD screen, current, voltage, time, amper hour, message display, English language selection

Measurement: True RMS The current-voltage measurement, temperature measurement of the pool

Output Control: 0-100% between the current - voltage control Pulse-Base Control: Optional

Cooling: Air, Oil, Water, Mixed

Cabin (Air - Water Cooled): Modular mounted, painted, standing or wheeled steel chassis

Boiler (oil cooling): Wave-walled, sanded, phosphated, interior and exterior painted, wheeled steel boiler

Installation: standardized, modular system

Transformer: High-efficiency, transformer Mak Plus Rectifier TSE

Color: Standard: Cream and Green / Option: RAL colors Catalogue

Programmed Operation: Automatic coating thickness control, Micron calculation system, 10 different programs

Timer: Default

Amperehour Counter: Process and total amperehour counter, the set value, dosing information, programs to choose from within the ampereminute or amperesecond

Ramp Function: The user-defined, unlimited

Pool Temperature Control: the specified limits, to control the cooling system

Remote Control: External operator panel, with communication cable RS485, 1 km. from a distance of portable, wireless 100 mt. up to a distance, has all the functions

Warning: Rectifier fault and status relay information

Protection Features: Phase missing, over current, overheat, short circuit