Battery Formation Devices

Formation Device is a device which has developed to polarize the battery plates with the best performance.The rectifier is manufactured in order to provide operator to load different current and time programs.Besides pole changing process can be made internally by the rectifier.User can choose desired polarity on each program.

Formation device is equipped with microprocessor control unit.By this program is done safely without the operator following the device.The device automatically shuts down at the end of the program.There is a user programmable control unit on the device.With the screen on this unit operator can monitor the device and have an idea about the problems by the messages on the screen.

Formation device is equipped with microprocessor control unit.By this program is done safely without the operator following the device.The device automatically shuts down at the end of the program.There is a user programmable control unit on the device.With the screen on this unit operator can monitor the device and have an idea about the problems by the messages on the screen.

Battery Formation Device

Easy Installation

Long Operating Life

Full Automatic Operation Program English Control Panel

Smart Bug Tracker System

All Process Parameters Check

Enabling Spots

Temperature Measurement

Display Error Messages

Choice of 20 Different Programs

Auto stop at the end of operation

Auto Stop Error Situations

High Yield

Low Maintenance Requirements

Easy to supply Standard Parts

Quiet Operation

Green Design

Energy-Efficient System

Aesthetic Appearance

Long Operating Life

Full Automatic Operation Program English Control Panel

Smart Bug Tracker System

All Process Parameters Check

Enabling Spots

Temperature Measurement

Display Error Messages

Choice of 20 Different Programs

Auto stop at the end of operation

Auto Stop Error Situations

High Yield

Low Maintenance Requirements

Easy to supply Standard Parts

Quiet Operation

Green Design

Energy-Efficient System

Aesthetic Appearance

Optional Specification

Wide Input Voltage Tape

Voice Error Alerts

PC /PLC Connection

Battery and Plate Temperature Measurement

Charge Current Control of Temperature Dependent*It is used during battery production process for dry plate charge and wet battery charge.

Wide Input Voltage Tape

Voice Error Alerts

PC /PLC Connection

Battery and Plate Temperature Measurement

Charge Current Control of Temperature Dependent*It is used during battery production process for dry plate charge and wet battery charge.

Technical Specification

Operation: Manual operator panel/automation system

Control: MRS Microprocessor Control System

Input Voltage: 3x380V AC,50Hz three-phase.

Output Voltage: 300V DC

Output Current: 0..500A

Measurement: DC Current-Voltage /Battery and cooling water temperature measurement

Yield: 90%

Highlights: Touch screen operator panel color

Output Control: 0-100%between the current-voltage regulation

Cooling: Air

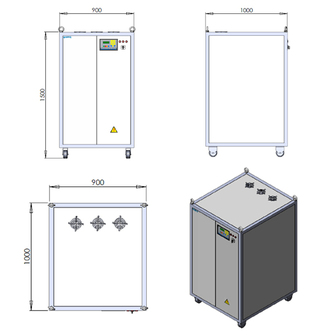

Cabins: modular assembly, painted, standing or wheeled steel chassis

Transformer: High-efficiency, transformer Mak plus rectifier solution TSE

Color: RAL7032

Programmed Operation: Everyone of 20 different 20-step program. According to the temperature of the battery current control

Timer: 99 hours timer at each step.

Ampere hour Counter: Process and total ampere hour counter, dispensing knowledge of the set value

Remote Control: External operator panel

Warning: Failure and status information relays

Protection Features: Phase error/Over current heat

Optional: Charge-Discharge Operation

Control: MRS Microprocessor Control System

Input Voltage: 3x380V AC,50Hz three-phase.

Output Voltage: 300V DC

Output Current: 0..500A

Measurement: DC Current-Voltage /Battery and cooling water temperature measurement

Yield: 90%

Highlights: Touch screen operator panel color

Output Control: 0-100%between the current-voltage regulation

Cooling: Air

Cabins: modular assembly, painted, standing or wheeled steel chassis

Transformer: High-efficiency, transformer Mak plus rectifier solution TSE

Color: RAL7032

Programmed Operation: Everyone of 20 different 20-step program. According to the temperature of the battery current control

Timer: 99 hours timer at each step.

Ampere hour Counter: Process and total ampere hour counter, dispensing knowledge of the set value

Remote Control: External operator panel

Warning: Failure and status information relays

Protection Features: Phase error/Over current heat

Optional: Charge-Discharge Operation